When winter storms approach, this article is in response to visitor requests for information on converting engines for use with propane.

INFORMATIONAL TIP ONLY — TheEpicenter.com does not sell or offer technical support for Propane Conversion Kits! Contact U.S. Carburetion in West Virginia for Propane Conversion Kits.

This tip will discuss conversion of a specific family of engines, namely the Tecumseh brand of vertical shaft or horizontal shaft engines, and a specific carburetor (also Tecumseh brand) for use with propane fuel. However, the discussion is applicable to other engine manufactures, engine models and carburetors. Check with state and local authorities for applicable codes. Please see safety notes below.

Safety Notes

Engine conversions must be carried out by qualified technicians and/or persons who will follow all safety guidelines as contained in pamphlets NFPA 54, 58, 38 or any other publication or guidelines stipulated by local, state or federal agencies and the authority having jurisdiction. As a starting point, contact your local fire department, propane supplier and insurance company for guidance. They will be able to direct you to the correct local governmental department for additional state and local requirements.The manufacturer of these kits reminds us that they are NOT approved for use indoor use!

For information on propane safety, publications may be ordered through The National Fire Protection Association (http://www.nfpa.org).

A partial list of applicable publications are shown below:

- NFPA 37: Standard for the Installation and Use of Stationary Combustion Engines and Gas Turbines, 1998 Edition

- NFPA 54: National Fuel Gas Code, 1999 Edition (National Fuel Gas Code provides safety requirements for fuel gas equipment installations, piping, and venting.

- NFPA 58: Liquefied Petroleum Gas Code, 1998 Edition. (Standard for the Storage and Handling of Liquefied Petroleum Gases, which provides the standard for the installation of the propane storage tank and piping to the first stage pressure regulator.)

Tecumseh Horizontal and Vertical Shaft Engines

In this project we used Tecumseh brand engines with heavy cast iron flywheels. This is a must have feature necessary for easy starting and smooth operation. Both of the engines we have used were 5 HP models.

In this project we used Tecumseh brand engines with heavy cast iron flywheels. This is a must have feature necessary for easy starting and smooth operation. Both of the engines we have used were 5 HP models.

Both engines used the same carburetor, so the discussion below applies to both the Horizontal and Vertical engines.

Typical conversion kits require modification to the carburetor, and once modified, the carburetor can not be used for gasoline. So, if you plan to install a propane kit, you might want to also purchase a replacement carburetor so you can swap back to a gas powered configuration if needed.

Why use Propane?

Propane is easy to store in large containers, and doesn't require special treatment for it to last a long time. It is commonly used for outdoor barbecues, but also for cooking and heating in homes and trailers. Propane is sometimes used to power refrigerator units in portable applications. It can be stored in refillable containers that can be refilled at many locations friendly to motor homes, travel trailers and such. Many folks in rural areas have propane delivered to large stationary tanks on their own property.

Propane is easy to store in large containers, and doesn't require special treatment for it to last a long time. It is commonly used for outdoor barbecues, but also for cooking and heating in homes and trailers. Propane is sometimes used to power refrigerator units in portable applications. It can be stored in refillable containers that can be refilled at many locations friendly to motor homes, travel trailers and such. Many folks in rural areas have propane delivered to large stationary tanks on their own property.

Since propane can be used for so many applications (cooking, heating etc), it's an ideal fuel for a generator as well. I like the idea of having one type of fuel source stored that I can use in a variety of ways.

What's involved in making an engine run on propane?

The existing carburetor on the engine must be modified to deliver propane into the combustion chamber. It sound simple, and it really is.

The existing carburetor on the engine must be modified to deliver propane into the combustion chamber. It sound simple, and it really is.

Basically, instead of delivering vaporized gasoline as the engine sucks in the air/fuel mixture during the "intake" cycle, the carburator delivers a propane/air mixture. The engine itself is not modified in any way. It still sucks in the air/fuel mixture, compresses it, ignites it and converts the resulting explosion (internal combustion) into rotary energy during the power stroke. Thus delivering work energy to the item which requires power (to rotate a generator armature for example).

The waste products are still expelled in the exhaust stroke, and the process continues, over and over. It's like using little controlled explosions to rotate the output shaft. Suck it in, compress it until it's explosive, blow it up, and use the explosive energy to rotate the output shaft. That's the way an engine works!

OK, enough said... A propane conversion just swaps one kind of fuel for another, and the other principals are the same.

So how does a conversion kit work?

We contacted the experts in carburetion and asked for help! They said, "been there, done that, been doing it for years." The key is a vacuum controlled flow rate regulator, linked directly to a modified carburetor.

We contacted the experts in carburetion and asked for help! They said, "been there, done that, been doing it for years." The key is a vacuum controlled flow rate regulator, linked directly to a modified carburetor.

This conversion kit works because the air/fuel mixture is automatically adjusted as load changes are made. This automatic adjustment is only possible because this special flow regulator is linked by a vacuum hose to the carburetor itself.

INFORMATIONAL TIP ONLY — TheEpicenter.com does not sell or offer technical support for Propane Conversion Kits! Contact U.S. Carburetion in West Virginia for Propane Conversion Kits.

This allows the flow regulator to automatically sense changes in engine intake vacuum which is directly related to engine load changes. So, if more load is added, the carburetor throttle changes, which causes an increase in intake manifold vacuum. And this vacuum causes the flow regulator in the propane conversion kit to increase fuel flow to keep the air/fuel mixture ideal. Without this feedback, it's impossible to keep the fuel/air mixture ideal and the motor running!

At the heart of the conversion is the modification of a carburetor to deliver the alternative fuel, and to provide a feedback method (a port to the vacuum inside the carburetor) to an external propane fuel delivery flow regulator, which is designed to accept the vacuum feedback and adjust the fuel delivery flow rate. This special vacuum flow regulator is like having an extra hand automatically adjusting the regulator output knob, keeping the air/fuel mixture ideal!

At the heart of the conversion is the modification of a carburetor to deliver the alternative fuel, and to provide a feedback method (a port to the vacuum inside the carburetor) to an external propane fuel delivery flow regulator, which is designed to accept the vacuum feedback and adjust the fuel delivery flow rate. This special vacuum flow regulator is like having an extra hand automatically adjusting the regulator output knob, keeping the air/fuel mixture ideal!

As with all of the Emergency & Power Generation articles published atTheEpicenter.com, we have tried to be technically correct in our discussion. As always, I'm sure we will be corrected here or there, but what I'm trying to get across is that the conversion is fairly straight forward. The most difficult part of the conversion is drilling one hole in the carburetor.

So without further delay, lets talk about what's involved in converting one of these engines with an off the shelf conversion kit to run on propane:

So what's involved?

The main task in modifying the carburetor is to replace the existing gasoline fuel delivery tube (the red plastic tube) with a brass propane delivery tube.

The main task in modifying the carburetor is to replace the existing gasoline fuel delivery tube (the red plastic tube) with a brass propane delivery tube.

To do this will require drilling out the opening in the carburetor where the old jet was located. The new brass jet (and some other fittings and a valve assembly) will take the place of the gasoline delivery jet.

Another brass fitting (the slow running fitting) will be replaced with a larger (hollow) fitting, which will serve as a vacuum feedback port to the vacuum controlled flow regulator.

Unused air passages which are only required for gasoline fuel use will be sealed with RTV silicone.

The steps are best described in a series of photographs.

(The photos shown below are for a specific model of carburetor but the modifications are similar on all carburators.)

|

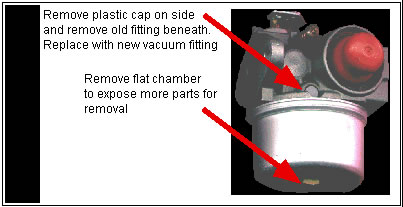

Step One: Remove the float chamber and plastic cap over vacuum fitting location. |

|

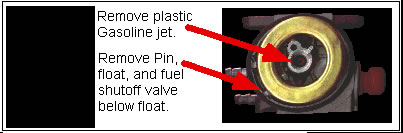

Step Two: Remove the Gasoline jet, float, and fuel shut-off valve. |

|

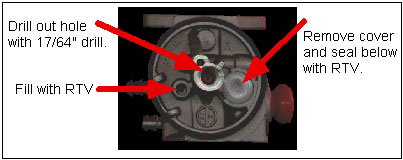

Step Three: Enlarge the location of the fuel delivery jet to accept the new propane jet, and seal unused passages. |

|

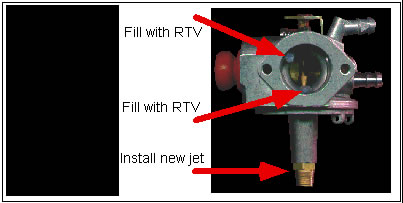

Step Four: Install propane delivery jet, and seal unused vents and air passages. |

|

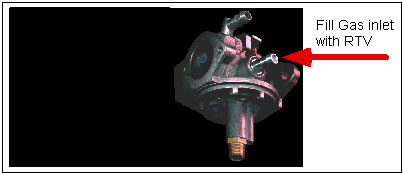

Step Five: Seal unused gasoline fuel inlet. |

|

Spare parts from the original carburetor that are not required. |

What does it look like when things are hooked up?

Here the system is shown before being installed on an engine (for clarity). The second, smaller hose is connected to the side of the carburetor where the vacuum fitting has been installed. The other end connects to the vacuum control feedback port on the flow regulator. The third hose connected to the vacuum flow regulator could either be connected to the low pressure household feed for natural gas use; or, with the a portability tank kit, it can be connected to a portable propane tank using the special 12 PSI regulator included with the portability kit.

Here the system is shown before being installed on an engine (for clarity). The second, smaller hose is connected to the side of the carburetor where the vacuum fitting has been installed. The other end connects to the vacuum control feedback port on the flow regulator. The third hose connected to the vacuum flow regulator could either be connected to the low pressure household feed for natural gas use; or, with the a portability tank kit, it can be connected to a portable propane tank using the special 12 PSI regulator included with the portability kit.

NOTE: In this project we used our direct drive alternator bracket and couplers to connect a 93 amp GM alternator and charging cables to the propane powered motor.

Some common questions and answers

Q. Where can I buy a kit like this?

A. We do not sell propane conversion kits at TheEpicenter.com. But there are many companies that do! The best thing to do is search the Internet. Enter "propane conversion" and the brand of your motor (i.e., "Briggs & Stratton propane conversion kit") in your browser's search bar.

Q. The Tecumseh kit you used looked like there were other smaller parts. What else was included?

A. The kit we used was custom designed to include every gizmo needed for the Tecumseh engine.

It included all the little stuff that would have taken time at the hardware store to round up.

It included all the little stuff that would have taken time at the hardware store to round up.

- Special vacuum controlled flow regulator

- Right angle brass fitting for fuel inlet to pressure regulator

- Right angle fitting for pressure regulator vacuum control line

- Two piece carburetor fuel delivery tube and flow control load block

- Brass Vacuum idle fitting for carburetor

- A right angle fuel outlet adapter to connect the regulator to the output supply tube

- Fuel hose regulator outlet to carburetor

- Two fuel hose clamps for regulator outlet to carburetor

- Vacuum hose from carburetor to regulator

- Wire ties for vacuum line

- Regulator mounting bracket

- Self drilling screws for attaching regulator mounting bracket

- Tube of 777 silicon sealant for filling unused passages in carburetor

- A tube of special thread sealing paste

- A Governor override kit consisting of a spring, eyelets and S-hooks which insure the carburetor is in an idle position when started

- Complete instillation manual with diagrams and detailed instructions

Q. How much propane will a motor use compared to gasoline?

A. About the same amount of propane as your motor uses in Gasoline. Propane has about 10% fewer British Thermal Units (BTU's) than Gasoline does. But the estimate for your engine running on gasoline in terms of hours per gallon will be very close to that for propane.

Q. What is the "portability kit" you mentioned? Do I need that too?

A. Yes in most applications.

The basic kit is designed to tie into the output of a regulator on a bulk propane tank. Small portable propane tanks (like barbecue tanks) do not have a regulator. The "portability kit" contains the required 12 PSI regulator, and a 12 foot hose. This kit is only required for use with portable tanks. It then feeds the vacuum controlled flow regulator that connects with the modified carburetor.

Q. How long does the kit take to install, and can I do it with just a few tools?

A. The kit took about 2 hours to complete the installation. But we couldn't try it out for 24 hours until the RTV had set up. Also, you will need some common tools like screw drivers, socket set and such, and a 17/64th drill bit and power drill.

PLEASE NOTE: TheEpicenter.com DOES NOT SELL Propane Conversion Kits! Please do not call us about propane conversions. For conversion kits, you may want to contact U.S. Carburation in West Virginia at 1-800-553-5608.

For folks who haven't seen our other tips on Emergency Generators, follow the links below:

- More homemade generator projects - Additions to vertical and horizontal projects, as well as info on direct drive!

- Build a high power AC/DC system - Massive AC and DC from the same system.

- Build a generator from a lawn edger (Part 1) - Use a horizontal gas motor to build your own generator.

- Build a generator from a lawn mower engine (Part 2) - Use a vertical shaft motor to build your own generator.

- Emergency Power - Lights and Generators, Part 1 - Everything you ever (or never) wanted to know...

- Emergency Power - Lights and Generators, Part 2 - More of everything you ever wanted to know...